AEROPLANE Magazine October 2009

Continued

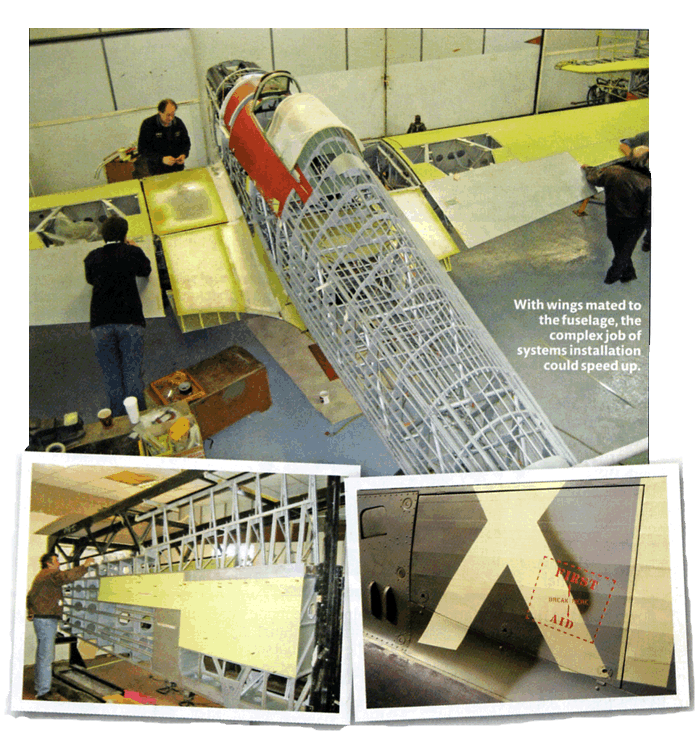

The partly restored Fuselage and Centre Section in March 2007. On the firewall is the coolant header tank. |

Getting it right Steve Atkin, an architect by day and a Hangar 11 volunteer in his spare time, researched the paint scheme and masterminded the replica bombs. “The bomb project was done by Hangar 11, in conjunction with Sywell Aviation Museum, who make the fins for us”, Steve says. “An original 250lb bomb was loaned by the RAF Museum, and moulded in glass fibre for us by a specialist company. |

Hangar 11's Chief Engineer Chris Norris examining the port wing as skinning gets under way in March 2008. Detailed stencilling on the fuselage. |

|

The metal fittings were made by Eyetech Engineering to our drawings. We worked closely with HRL to ‘reverse engineer’ some missing parts of the bomb carriers. A lot of work went into getting them on to the aircraft, as no other complete original units existed. The job was complicated by the fact that the Hurricane fitment was heavily modified from the Air Ministry standard carriers. |

|

Above from left : the rear outer-wing attachment point on the centre section; a cluster joint between fuselage and centre section; the pneumatic-system air bottle which supplies the brakes and gun-cocking mechanism; the rebuilt Packard Merlin 29 engine arrives. |

|

Above from left : A bomb rack; the bomb-release switch panel in the lower right-hand ride of the cockpit; the starboard wing gun-bay, showing the 0.303in Browning machine guns and ammunition feeds; the unusual configuration of the two outer guns on the port wing. |

|

In the air |

|

|

|

| Back | Next |